In the fall and winter seasons, as the relative humidity in the air decreases and the temperature difference between morning and evening increases, the surface of the adhesive joints of glass curtain walls and aluminum panel curtain walls will gradually become protruding and deformed at various construction sites. Even some door and window projects may experience surface deformation and protrusion of the adhesive joints on the same day or within a few days of sealing. We call it the phenomenon of sealant bulging.

1. What is sealant bulging?

The curing process of single component construction weatherproof silicone sealant relies on reacting with moisture in the air. When the curing speed of the sealant is slow, the time required for sufficient surface curing depth will be longer. When the surface of the sealant has not yet solidified to a sufficient depth, if the width of the adhesive seam changes significantly (usually due to the thermal expansion and contraction of the panel), the surface of the adhesive seam will be affected and uneven. Sometimes it is a bulge in the middle of the entire adhesive seam, sometimes it is a continuous bulge, and sometimes it is a twisted deformation. After the final curing, these uneven surface adhesive seams are all solid inside (not hollow bubbles), collectively referred to as "bulging".

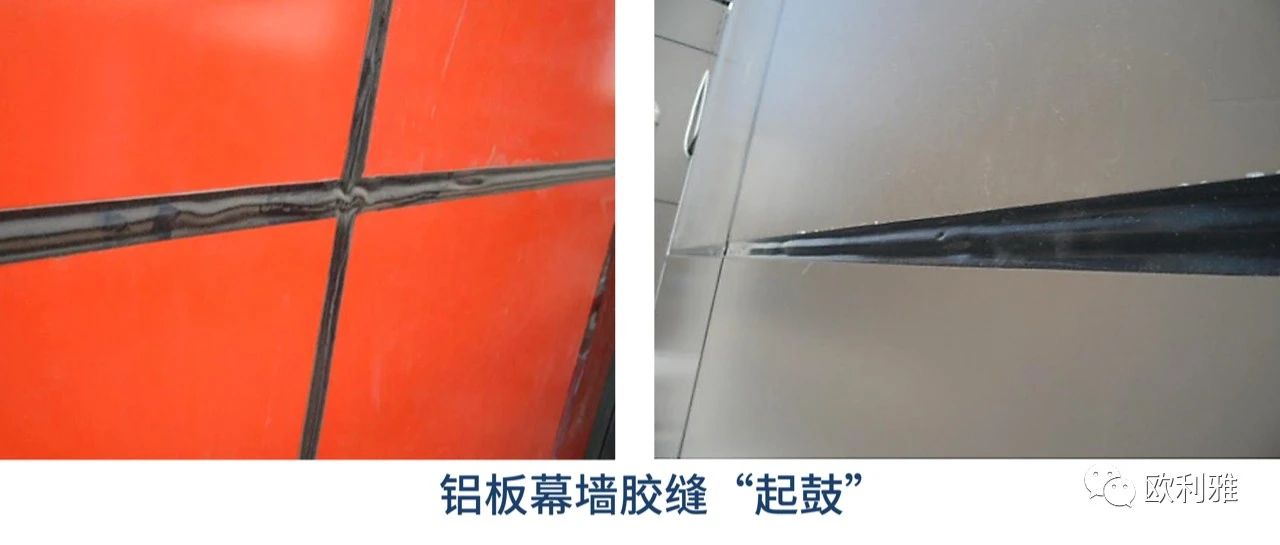

The bulging of adhesive seam of aluminum curtain wall

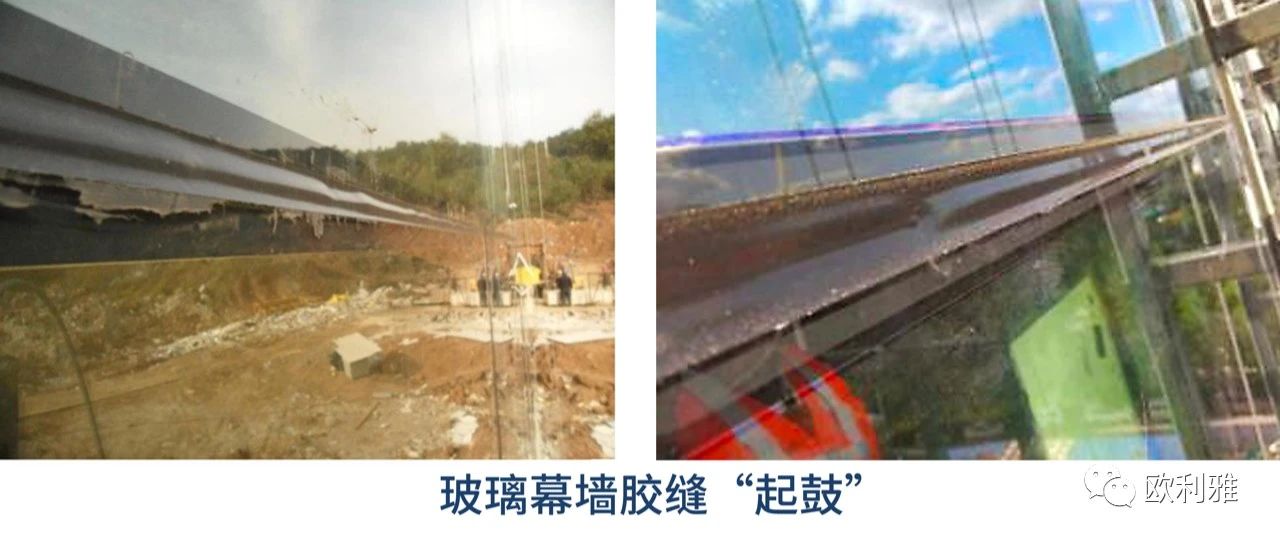

The bulging of adhesive seam of glass curtain wall

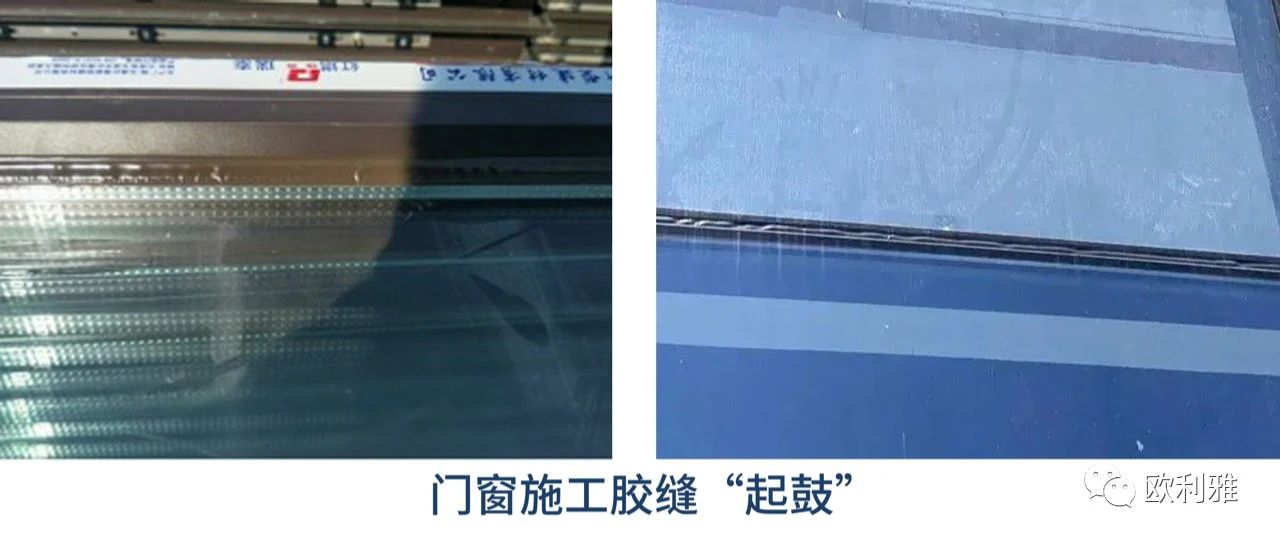

The bulging of adhesive seam of door and window construction

2. How does Bulging happen?

The fundamental reason for the phenomenon of "bulging" is that the adhesive undergoes significant displacement and deformation during the curing process, which is the result of a comprehensive effect of factors such as the curing speed of the sealant, the size of the adhesive joint, the material and size of the panel, the construction environment, and the construction quality. To solve the problem of bulging in adhesive seams, it is necessary to eliminate the unfavorable factors that cause bulging. For a certain project, it is generally difficult to manually control the environmental temperature and humidity, and the panel material and size, as well as the design of the adhesive joint, have also been determined. Therefore, control can only be achieved from the type of sealant (adhesive displacement capacity and curing speed) and environmental temperature difference changes.

A. The movement capability of sealant:

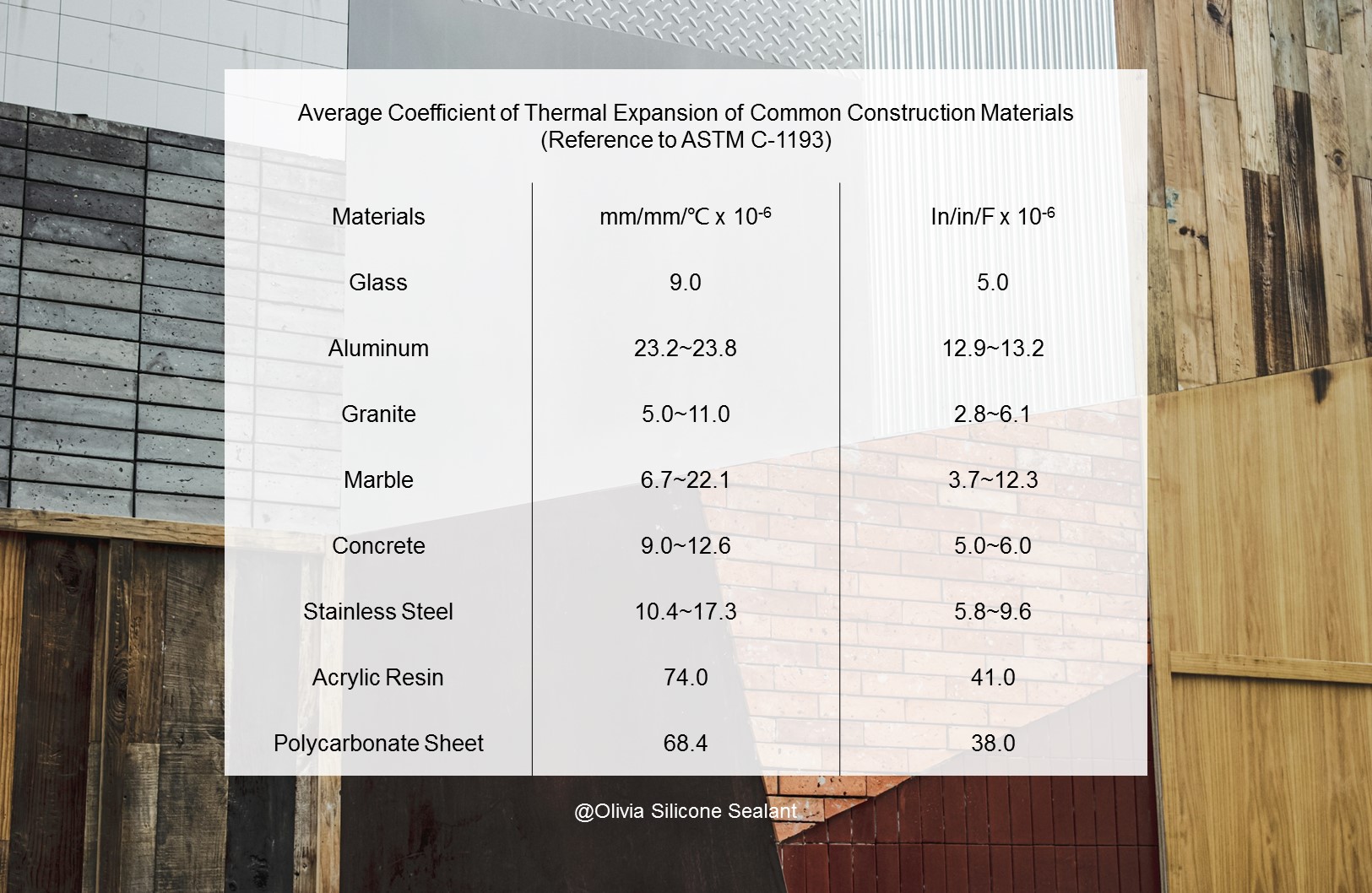

For a specific curtain wall project, due to the fixed values of plate size, panel material linear expansion coefficient, and annual temperature change of the curtain wall, the minimum movement capability of the sealant can be calculated based on the set joint width. When the joint is narrow, a sealant with higher movement capability needs to be selected to meet the requirements of joint deformation.

B. Curing speed of sealant:

At present, the sealant used for construction joints in China is mostly neutral silicone adhesive, which can be divided into oxime curing type and alkoxy curing type according to the curing category. The curing speed of oxime silicone adhesive is faster than that of alkoxy silicone adhesive. In construction environments with low temperatures (4-10 ℃), large temperature differences (≥ 15 ℃), and low relative humidity (<50%), the use of oxime silicone adhesive can solve most of the "bulging" problems. The faster the curing speed of the sealant, the stronger its ability to withstand joint deformation during the curing period; The slower the curing speed and the greater the movement and deformation of the joint, the easier it is for the adhesive joint to bulge.

C. Temperature and humidity of the construction site environment:

Single component construction weatherproof silicone sealant can only cure by reacting with moisture in the air, so the temperature and humidity of the construction environment have a certain impact on its curing speed. Generally speaking, higher temperature and humidity result in faster reaction and curing speed; Low temperature and humidity result in a slower curing reaction speed, making it easy for the adhesive seam to bulge. The recommended optimal construction conditions are: ambient temperature between 15 ℃ and 40 ℃, relative humidity>50% RH, and glue cannot be applied during rainy or snowy weather. Based on experience, when the relative humidity of the air is low (humidity hovers around 30% RH for a long time), or there is a large temperature difference between morning and evening, the temperature during the day may be around 20 ℃ (if the weather is sunny, the temperature of aluminum panels exposed to the sun can reach 60-70 ℃), but the temperature at night is only a few degrees Celsius, so bulging of curtain wall adhesive joints is more common. Especially for aluminum curtain walls with high material linear expansion coefficients and significant temperature deformation.

D. Panel material:

Aluminum plate is a common panel material with a higher coefficient of thermal expansion, and its linear expansion coefficient is 2-3 times that of glass. Therefore, aluminum plates of the same size have greater thermal expansion and contraction deformation than glass, and are more prone to large thermal movement and bulging due to changes in temperature difference between day and night. The larger the size of the aluminum plate, the greater the deformation caused by temperature difference changes. This is also why the same sealant may experience bulging when used on certain construction sites, while in some construction sites, bulging does not occur. One reason for this may be the difference in the size of the curtain wall panels between the two construction sites.

3. How to prevent sealant from bulging?

A. Choose a sealant with a relatively fast curing speed. The curing speed is mainly determined by the formula characteristics of the sealant itself, in addition to environmental factors. It is recommended to use our company's "winter quick drying" products or adjust the curing speed separately for a specific usage environment to reduce the probability of bulging.

B. Construction time selection: If the relative deformation (absolute deformation/joint width) of the joint is too large due to low humidity, temperature difference, joint size, etc., and no matter what sealant is used, it still bulges, what should be done?

1) Construction should be carried out as soon as possible on cloudy days, as the temperature difference between day and night is small and the deformation of the adhesive joint is small, making it less prone to bulging.

2) Take appropriate shading measures, such as using dust nets to cover scaffolding, so that the panels are not directly exposed to sunlight, reduce the temperature of the panels, and minimize joint deformation caused by temperature differences.

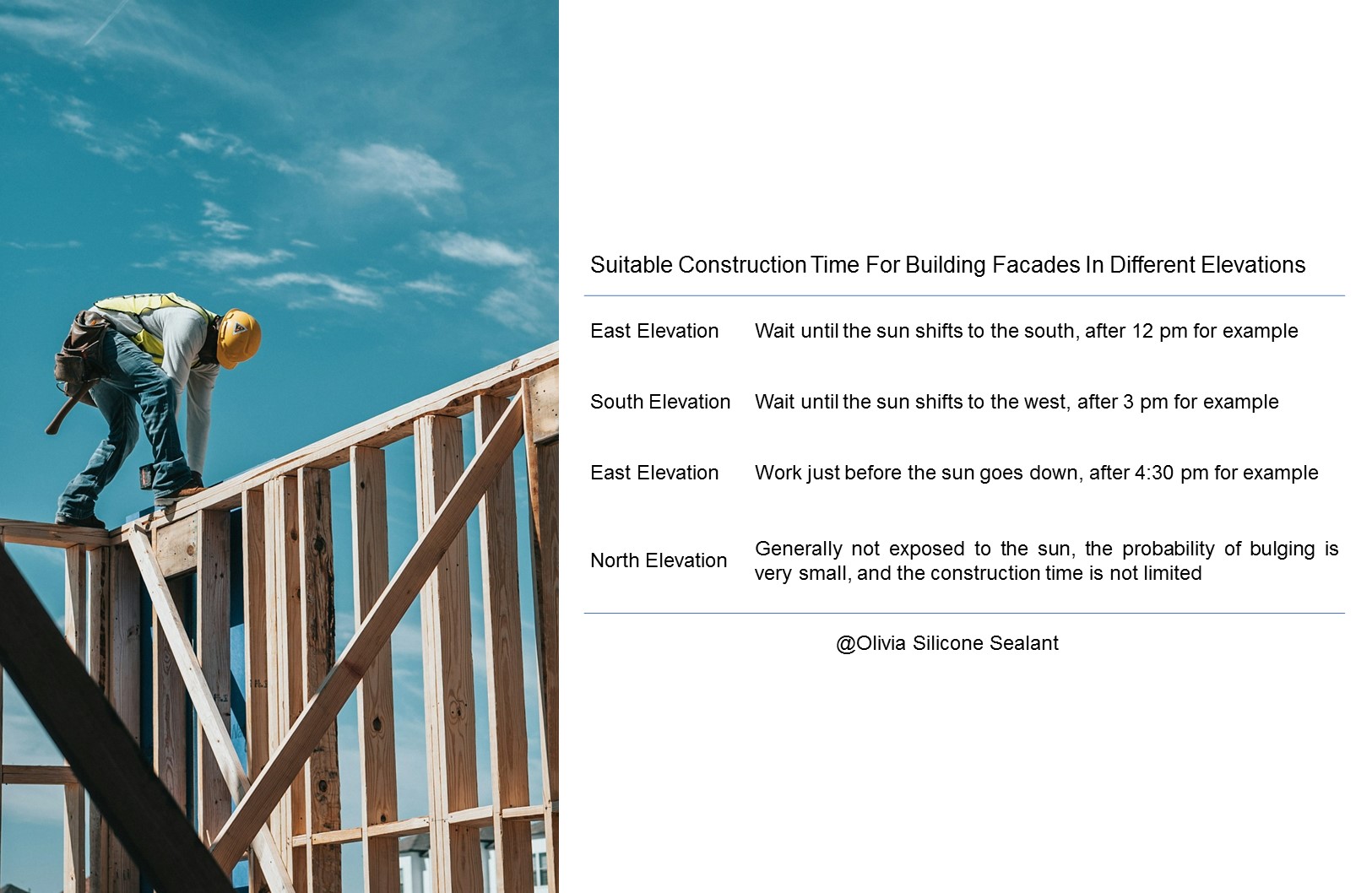

3) Choose the appropriate time to apply sealant.

C. The use of perforated backing material facilitates air circulation and accelerates the curing speed of the sealant. (Sometimes, because the foam rod is too wide, the foam rod is pressed in and deformed during construction, which will also lead to bulge).

D. Apply a second layer of adhesive to the joint. First, apply a concave adhesive joint, wait for it to solidify and become elastic for 2-3 days, then apply a layer of sealant on its surface. This method can ensure the smoothness and aesthetics of the surface adhesive joint.

In summary, the phenomenon of "bulging" after sealant construction is not a quality problem of the sealant, but a combination of various unfavorable factors. The correct selection of sealant and effective construction prevention measures can significantly reduce the probability of "bulging" occurrence.

[1] 欧利雅. (2023). 小欧老师讲解密封胶“起鼓”原因及对应措施.

Statement: some pictures come from the Internet.

Post time: Jan-31-2024